FRP Lining

Japan: Patent No. 3594183

FRP lining on underground tanks

stops deterioration from inside almost permanently.

FRP lining perfectly prevents leak of hazardous materials by applying FRP on the inside of tanks. In FRP lining sheet method, oil/chemical proof FPR sheets produced in our factory are applied to tank inside and hardened by ultraviolet ray. This prevents corrosion from inside almost permanently and provides the tank with similar function as if it were a double shell tank after the completion.

-

1. Service station can continue to operate during the tank lining

2. Cut on access hole on the top of the tank

5. Safety level check by interior inspection

-

3. Much rust in the tank

6. Installation of FRP lining inside the tank

-

Before rubbing rust

Before rubbing rust After rubbing rust

After rubbing rust4. Surface preparation

7. Installation of manhole for the next inspection

FEATURES

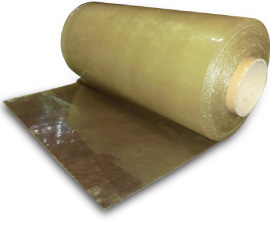

Rolled FRP sheet

[manufactured in house and sold]

- Tank interior lining (sheet method)

- Thickness is uniform and finished quality is high because this method is free from material drooping on the interior top which is apt to occur in the hand lay-up method.

- Hardened by ultraviolet ray [20 to 30 minutes]

- There is no heat generation during hardening process, and no defect on tank exterior protection material. Installation is possible even in winter.

- Short work period

- Since FRP lining on 2 units of 10 KL tanks are done simultaneously, the whole work can be completed within 5 to 10 days (depending on whether the tank has an openning or not)